Electric Trunnion Mounted Ball Valve (Metal Seated) - High Pressure & Temp | DELCO

The DELCO DK62-Q-2PF is a severe-service Electric Trunnion Mounted Ball Valve designed for high-pressure, high-temperature, and abrasive applications. Featuring a Metal-to-Metal (Hard Sealed) seat and a rugged Trunnion structure, it withstands harsh conditions where soft seats fail. Powered by a heavy-duty electric actuator with a high-torque gearbox, it ensures reliable isolation in Oil & Gas, Mining, and Power industries. Available in DN15–DN350, up to Class 600/PN100, in WCB or Stainless Steel (CF8M).

Size Range: DN15-DN350

Size Range: DN15-DN350

Material: WCB, Stainless Steel etc.

Material: WCB, Stainless Steel etc.

Connection Standard:GB / ANS / JIS / DIN

Connection Standard:GB / ANS / JIS / DIN

Features

Engineered for critical isolation, combining a rigid trunnion design with wear-resistant hardening technologies:

✅Trunnion Mounted for High Stability

The ball is anchored at the top and bottom (trunnion), absorbing the line pressure load directly into the body rather than the seat. This design significantly lowers operating torque and ensures reliable sealing performance under high pressures (up to ASME Class 600/900).

✅Metal-to-Metal Hard Sealing

Designed for extreme temperatures (up to 450°C+) and abrasive media. The ball and seats undergo surface hardening treatments (such as Stellite overlay, Tungsten Carbide coating, or Nitriding) to resist wear from slurries, coal powder, and steam, ensuring zero-leakage performance over a long lifespan.

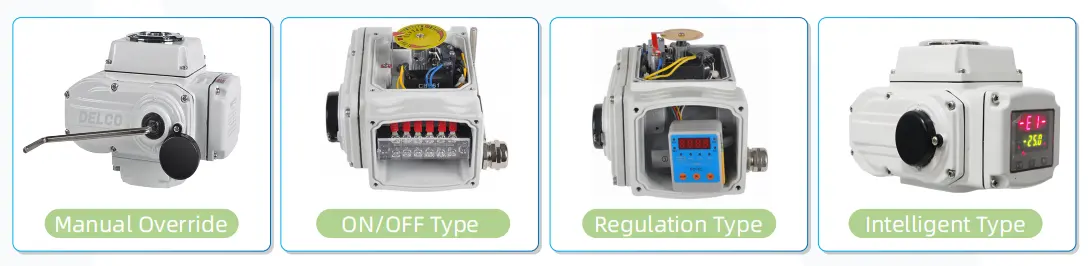

✅High-Torque Electric Actuation

Equipped with a robust Multi-Turn Electric Actuator coupled with a Worm Gearbox. This combination converts high-speed electric motor output into the massive quarter-turn torque required to seat and unseat the metal ball valve, providing smooth and powerful operation.

✅Premium Materials (CF8M/WCB)

The valve body is heavy-wall cast in Carbon Steel (WCB) for general high-pressure use or Stainless Steel (CF8M/SS316) for superior corrosion resistance in aggressive chemical environments. The blowout-proof stem ensures safety standards are met.

✅Global Flange & Safety Standards

Built to strictly comply with API 6D, ASME B16.34, and ISO standards. Features include an anti-static device and fire-safe design (API 607/API 6FA), making it a trusted choice for refinery and pipeline projects worldwide.

Photo

Photo

Industry Applications

-

Oil & Gas

Electric actuators enable reliable remote shutoff and precise positioning for pipeline and process valves. Optional on/off or modulating control with feedback signals. -

Chemical & Petrochemical

Stable electric actuation for corrosive-duty applications. Supports modulating control and position feedback to match PLC/DCS requirements. -

Power Generation

Designed for power plants where dependable actuation and accurate positioning are required on steam/water auxiliary lines and balance-of-plant systems. -

Food & Pharmaceutical

Electric actuation for sanitary valve automation. Clean operation with configurable control and feedback—confirm enclosure and material requirements by application. -

Water & Wastewater

Ideal for treatment plants and pump stations—remote on/off or modulating control, position indication/feedback, and continuous field operation. -

HVAC & District Heating

Accurate valve actuation for energy-efficient HVAC networks. Smooth flow regulation with modulating control options.

Browse our case studies or talk directly with our engineers to discuss your application.

Send Your Inquiry

Not sure which valve fits your project? Our engineers provide fast selection support and OEM customization.

For a faster and more precise quotation, kindly include details such as:

- The model or features you are looking for

- Your estimated purchase quantity

- Any OEM / branding requirements

- Target market or application